New

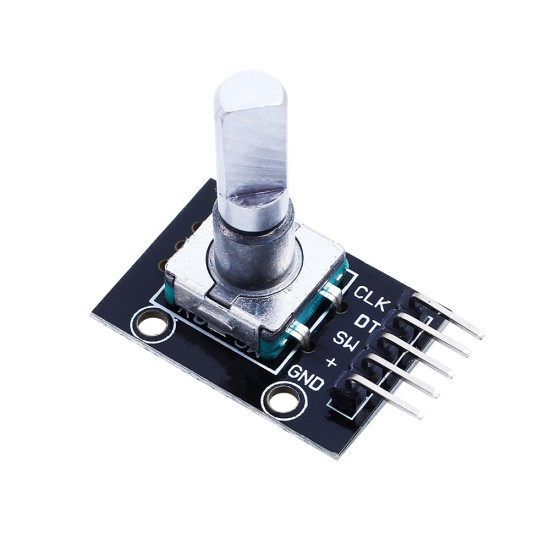

360-degree rotor encoder module KY-040

Rotating encoder module

Working voltage: 5V

A circle of pulses: 20

The rotary encoder can count the number of times of the output pulse during the rotation of the positive and opposite direction by rotating. The rotating count is not like a potential meter. This rotation count is not limited.With the buttons on the rotary encoder, you can reset to the initial state, that is, count from 0.

Working principle:

The incremental encoder is a rotating sensor that converts the rotary to a series of digital pulse signals.These pulses are used to control corner displacement.The conversion of the angle shift in the Eltra encoder uses the principle of photoelectric scanning.The reading system is based on the rotation of the radial score disk (code disk) composed of alternate light transmittance windows and opaque windows.EssenceThe receiver covers a layer of diffraction grating, which has the same window width as the code disk.The job of the receiver is to feel the change generated by the disc ring of the disc, and then converts the change of light to the corresponding electrical change.Then increase the low level signal to a higher level and generate a square pulse without any interference, which must be processed with electronic circuits.The reading system usually uses a differential method. The two waveforms are compared with different signals with the same aspect difference of 180 ° to improve the quality and stability of the output signal.The reading is formed on the basis of the difference between the two signals, which eliminates interference.

Increase encoder:

The incremental encoder gives a two -phase square wave. Their phase difference is 90 °, which is usually called A channel and B channel.One of the channels gives information related to speed, and at the same time, comparison through two channel signals to obtain information in the direction of rotation.There is also a special signal called Z or Zero -channel, which gives an absolute zero -bit of the encoder. This signal is a square wave with the central line of the A channel square wave.

The accuracy of incremental encoder depends on the two factors: mechanical and electrical factors. These factors are: grating error errors, discs of disc, bearing eccentricity, error of the introduction of electronic reading devices, and the inaccurate part of optical parts.The measurement unit that determines the precision of the encoder is the degree of electrical, and the accuracy of the encoder determines the pulse scores generated by the encoder.The following uses a 360 ° electrical degree to indicate the rotation of the mechanical axis, and the rotation of the shaft must be a complete cycle.You must know how much mechanical angle is equivalent to 360 degrees in electrical, you can use the following formulas to calculate: Electrical 360 = Mechanical 360 °/N ° Pulse/Rotation

Figure: A, B -turn signal

The encoder score error is represented by the maximum offset of the two continuous pulse waves from the perspective of electrical angle.The error exists in any encoder, which is caused by the aforementioned factors.The maximum error of the ELTRA encoder is ± 25 electrical angle (under any condition that has been declared), which is equivalent to the rated value offset ± 7%.The number of electrical degrees is equivalent to about ± 10%of the rated value.

UVW signal incremental encoder

In addition to the above -mentioned traditional encoders, there are some incremental encoders integrated with other electrical output signals.The incremental encoder integrated with the UVW signal is an instance, which is usually used to exchange feedback from AC servo motors.These magnetic pole signals generally appear in the AC servo motor. The UVW signal is generally designed by simulating the function of the original magnetic original.In the ELTRA encoder, these UVW signals are generated in optical methods and appeared in the form of three square waves. They have shifted to each other for 120 °.In order to facilitate the startup of motors, controlling the booter used by the motor requires these correct signals.These UVW magnetic pole pulses can be repeated many times in mechanical axis rotation, because they directly depend on the number of motor magnetic poles to be connected, and for the UVW signal of 4, 6 or more polar motors.

***********************************************************************************

Arduino test code:

int Redpin = 2;

int Yellowpin = 3;

int Greenpin = 4;

int Apin = 6;

int bpin = 7;

int buttonpin = 5;

int State = 0;

int LongPeriod = 5000; // Time at green or red

int shortperiod = 700; // Time Period When Changing

int TargetCount = ShortPeriod;

int count = 0;

void setup ()

{{

pinmode (apin, input);

pinmode (bpin, input);

pinmode (buttonpin, input);

pinmode (redpin, output);

pinmode (YELLOWPIN, OUTPUT);

Pinmode (GreenPin, Output);

}

void loop ()

{{

Count ++;

If (DigitalRead (Buttonpin))

{{

setlights (high, high, high);

}

else

{{

int Change = Getencoderturn ();

int newperiod = longperiod + (Change * 1000);

if (newPeriod >= 1000 && newpering

{{

longperiod = newperiod;

}

if (count >targetCount)

{{

setstate ();

count = 0;

}

}

delay (1);

}

int Getencoderturn ()

{{

// Return -1, 0, OR +1

static int Olda = Low;

static int oldb = low;

int Result = 0;

int newa = digitalread (apin);

int newsbb = digitalread (bpin);

if (newa! = Olda || Newb! = OLDB)

{{

// something has Changed

ifda == Low && Newa == High)

{{

result = - (OLDB * 2-1);

}

}

Olda = NEWA;

Oldb = newb;

Return result;

}

int setState ()

{{

if (State == 0)

{{

setlights (high, low, low);

targetCount = Longpering;

state = 1;

}

else if (state == 1)

{{

setlights (high, high, low);

targetCount = ShortPeriod;

state = 2;

}

else if (state == 2)

{{

setlights (Low, Low, High);

targetCount = Longpering;

state = 3;

}

else if (state == 3)

{{

setlights (LOW, HIGH, LOW);

targetCount = ShortPeriod;

state = 0;

}

}

void setlights (int Red, int Yellow, int Green)

{{

DigitalWrite (redpin, red);

DigitalWrite (YELLOWPIN, YELLOW);

digitalWrite (GreenPin, Green);

}

Working voltage: 5V

A circle of pulses: 20

The rotary encoder can count the number of times of the output pulse during the rotation of the positive and opposite direction by rotating. The rotating count is not like a potential meter. This rotation count is not limited.With the buttons on the rotary encoder, you can reset to the initial state, that is, count from 0.

Working principle:

The incremental encoder is a rotating sensor that converts the rotary to a series of digital pulse signals.These pulses are used to control corner displacement.The conversion of the angle shift in the Eltra encoder uses the principle of photoelectric scanning.The reading system is based on the rotation of the radial score disk (code disk) composed of alternate light transmittance windows and opaque windows.EssenceThe receiver covers a layer of diffraction grating, which has the same window width as the code disk.The job of the receiver is to feel the change generated by the disc ring of the disc, and then converts the change of light to the corresponding electrical change.Then increase the low level signal to a higher level and generate a square pulse without any interference, which must be processed with electronic circuits.The reading system usually uses a differential method. The two waveforms are compared with different signals with the same aspect difference of 180 ° to improve the quality and stability of the output signal.The reading is formed on the basis of the difference between the two signals, which eliminates interference.

Increase encoder:

The incremental encoder gives a two -phase square wave. Their phase difference is 90 °, which is usually called A channel and B channel.One of the channels gives information related to speed, and at the same time, comparison through two channel signals to obtain information in the direction of rotation.There is also a special signal called Z or Zero -channel, which gives an absolute zero -bit of the encoder. This signal is a square wave with the central line of the A channel square wave.

The accuracy of incremental encoder depends on the two factors: mechanical and electrical factors. These factors are: grating error errors, discs of disc, bearing eccentricity, error of the introduction of electronic reading devices, and the inaccurate part of optical parts.The measurement unit that determines the precision of the encoder is the degree of electrical, and the accuracy of the encoder determines the pulse scores generated by the encoder.The following uses a 360 ° electrical degree to indicate the rotation of the mechanical axis, and the rotation of the shaft must be a complete cycle.You must know how much mechanical angle is equivalent to 360 degrees in electrical, you can use the following formulas to calculate: Electrical 360 = Mechanical 360 °/N ° Pulse/Rotation

Figure: A, B -turn signal

The encoder score error is represented by the maximum offset of the two continuous pulse waves from the perspective of electrical angle.The error exists in any encoder, which is caused by the aforementioned factors.The maximum error of the ELTRA encoder is ± 25 electrical angle (under any condition that has been declared), which is equivalent to the rated value offset ± 7%.The number of electrical degrees is equivalent to about ± 10%of the rated value.

UVW signal incremental encoder

In addition to the above -mentioned traditional encoders, there are some incremental encoders integrated with other electrical output signals.The incremental encoder integrated with the UVW signal is an instance, which is usually used to exchange feedback from AC servo motors.These magnetic pole signals generally appear in the AC servo motor. The UVW signal is generally designed by simulating the function of the original magnetic original.In the ELTRA encoder, these UVW signals are generated in optical methods and appeared in the form of three square waves. They have shifted to each other for 120 °.In order to facilitate the startup of motors, controlling the booter used by the motor requires these correct signals.These UVW magnetic pole pulses can be repeated many times in mechanical axis rotation, because they directly depend on the number of motor magnetic poles to be connected, and for the UVW signal of 4, 6 or more polar motors.

***********************************************************************************

Arduino test code:

int Redpin = 2;

int Yellowpin = 3;

int Greenpin = 4;

int Apin = 6;

int bpin = 7;

int buttonpin = 5;

int State = 0;

int LongPeriod = 5000; // Time at green or red

int shortperiod = 700; // Time Period When Changing

int TargetCount = ShortPeriod;

int count = 0;

void setup ()

{{

pinmode (apin, input);

pinmode (bpin, input);

pinmode (buttonpin, input);

pinmode (redpin, output);

pinmode (YELLOWPIN, OUTPUT);

Pinmode (GreenPin, Output);

}

void loop ()

{{

Count ++;

If (DigitalRead (Buttonpin))

{{

setlights (high, high, high);

}

else

{{

int Change = Getencoderturn ();

int newperiod = longperiod + (Change * 1000);

if (newPeriod >= 1000 && newpering

{{

longperiod = newperiod;

}

if (count >targetCount)

{{

setstate ();

count = 0;

}

}

delay (1);

}

int Getencoderturn ()

{{

// Return -1, 0, OR +1

static int Olda = Low;

static int oldb = low;

int Result = 0;

int newa = digitalread (apin);

int newsbb = digitalread (bpin);

if (newa! = Olda || Newb! = OLDB)

{{

// something has Changed

ifda == Low && Newa == High)

{{

result = - (OLDB * 2-1);

}

}

Olda = NEWA;

Oldb = newb;

Return result;

}

int setState ()

{{

if (State == 0)

{{

setlights (high, low, low);

targetCount = Longpering;

state = 1;

}

else if (state == 1)

{{

setlights (high, high, low);

targetCount = ShortPeriod;

state = 2;

}

else if (state == 2)

{{

setlights (Low, Low, High);

targetCount = Longpering;

state = 3;

}

else if (state == 3)

{{

setlights (LOW, HIGH, LOW);

targetCount = ShortPeriod;

state = 0;

}

}

void setlights (int Red, int Yellow, int Green)

{{

DigitalWrite (redpin, red);

DigitalWrite (YELLOWPIN, YELLOW);

digitalWrite (GreenPin, Green);

}

| Product Attributes | |

| Brand | Other/Other |

| Model | Rotating encoder module |

Unlimited Blocks, Tabs or Accordions with any HTML content can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc. You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.

$0.47

- Stock: In Stock

- Model: ULLK1713

- Weight: 0.01kg